HomeResearchResearch Lines

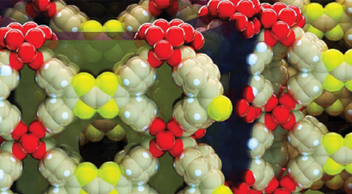

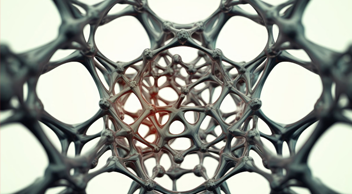

Metal-Organic Frameworks (MOFs)

Research objectives and activities O1.1) Unconventional methodologies for MOFs preparation and structural control. MOFs are commonly prepared by solvothermal synthesis, involving a solvent method at high temperatures. We have recently shown that alternative routes such as solvent-free methodologies allow the preparation of elusive MOFs that cannot be prepared under usual conditions (J.Am.Chem.Soc. 2019, 141, 7173; Chem.Sci. 2022, 13, 842; J.Am.Chem.Soc. 2023, 145, 23249). We will aim to generalize this novel approach to prepare elusive MOFs with reactive metal centers for catalysis, gas storage and separation, and sensing. O1.2) Responsive MOFs. The preparation of flexible stimuli-responsive MOFs allows the controlled modification of the pore size. We have shown the effect of the framework flexibility on different physical properties, such as redox (J.Am.Chem.Soc. 2019, 140, 10562) or catalysis (Chem.Commun. 2019, 55, 10932). We will explore different stimuli (light, pressure, electric field, guest molecule) to tune the structural features of MOFs that can adjust the pore size and modify its separation capacity towards different mixtures of gases. O1.3) Another instrumental feature of MOFs is the possibility of integrating multiple components. In this context, our work has demonstrated the importance of controlling this distribution to access synergies that translate into unique reactivities in catalysis (J.Am.Chem.Soc. 2023, 145, 3855), photocatalysis (J.Am.Chem.Soc. 2021, 143, 1798), or degradation of toxic agents (Chem 2020, 6, 3118). We will go one step-further by synthesizing, in large scale, heterometallic subnanometer metal clusters which are called to constitute a paradigmatic shift in catalysis given their unique electronic properties. O1.4) Processability of MOFs. One of the main pending objectives in the field of MOFs is their processability. We will use a simple, fast, continuous, and economically viable manner to scale up MOFs, as well as process them to allow for their application in a real environment. We will achieve this by using spray-drying under continuous flow technique, their integration within MOFs and manufacturing laboratory-scale capture devices with efficient capture behaviour.